|

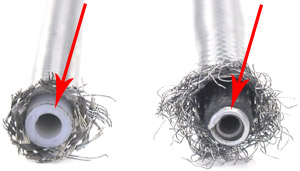

Another common

problem with some after market stainless steel braided cables is

their overall length shrink factor. As the cable is pulled, linear

pressure is placed on the nylon tubing inner liner (see picture

at the far left) of these cables. This causes the cable to physically

become shorter in length as the apply pressure is increased. The

factory throttle, detent and TV cables all use a steel lining (see

the picture on the right) which maintains its length under stress

and resists becoming shorter when pressure is applied!

The plastic tubing shrink problem gets progressively worse as the

engine compartment warms up since the plastic tubing is a thermoplastic

that becomes softer as it gets hotter! As this occurs, the actual

cable pull distance becomes less and less. A throttle cable with

this problem will stop reaching its full W.O.T. position; this results

in loss of high rpm power. Our personal experience with customer's

cars, that enter our shop which, have this style throttle cable system,

over 60% of them will not cause the carburetors linkage to reach

wide open when the engine is at operating temperature! The

owners are stunned to say the least! This condition can be easily

checked. Once the engine compartment is up to normal operating temperature,

shut the engine off and immediately have a friend press the accelerator

pedal to the floor, while you try to rotate the carburetor's linkage

further, if you can, you have the problem!

Lack of power if the throttle fails to reach its full wide open

position is not a serious problem, disappointing maybe, but will not

cause damage to anything. The effect this condition has on a Th-700R4

or Th-2004R is an entirely different situation and can have very

serious consequences. If the throttle linkage doesn't reach

its full wide open throttle position, the communications to the

transmission via the TV cable can't possibly perform its function

correctly!

The critical function of the TV cable system is to boost the operating

pressures as the throttle is applied. Increased boost pressures

are necessary to offset increased torque output from the vehicles

engine as the throttle is applied. A cable that changes length cannot

maintain its proper pull function. If engine torque production becomes

greater than the transmission hydraulic clamping pressures, clutches

and bands will slip, which can shorten the transmissions life dramatically,

especially in overdrive (fourth gear). This problem can dramatically

affect the shift characteristics of the transmission. Precise consistent

management of this critical system is absolutely necessary for correct

transmission operation and longevity. We prevent this problem by

using a steel lined cable instead of the nylon tubing as a conduit.

|